Ring PCB Technology Co.,Limited

From robotics and process automation to energy management and industrial IoT devices, PCBA are the core components ensuring seamless functionality and reliability. Since 2013, Ring PCB has been at the forefront of providing cutting-edge Industrial Control PCBA solutions from its state-of-the-art factory in Shenzhen, China.

The Importance of PCBA in Industrial Control Systems

- Programmable Logic Controllers (PLCs): Enabling precise automation of machinery and processes.

- Human-Machine Interfaces (HMIs): Allowing operators to interact with industrial systems.

- Motor Control Systems: Managing the speed, torque, and efficiency of industrial motors.

- IoT-Enabled Devices: Facilitating real-time monitoring and data collection in Industry 4.0 applications.

- Sensors and Actuators: Powering the feedback loops essential for automated systems.

Challenges in Industrial Control PCBA Manufacturing

1. Extreme Operating Conditions

Industrial environments can be harsh, with exposure to dust, moisture, temperature fluctuations, and electrical noise. PCBA must be designed to function reliably in such conditions.

Solutions:

- Robust Materials: We use high-performance laminates like FR4, PTFE, and heat-resistant substrates to ensure durability in extreme conditions.

- Conformal Coating: Our PCBA can be coated with a protective layer to shield components from moisture, dust, and chemical exposure.

- Thermal Management Solutions: We incorporate heat sinks, thermal vias, and advanced cooling techniques to manage high-power applications.

2. High Power and Current Requirements

Industrial equipment often involves high-power circuits, necessitating PCBA capable of handling significant current loads without overheating or failure.

Solutions:

- Heavy Copper PCBs: Since 2008, Ring PCB has been producing Heavy Copper PCBs, capable of supporting currents of up to 200 amps, making them ideal for industrial applications.

- Precise Soldering Processes: Our 8-stage lead-free reflow soldering and wave soldering processes ensure strong and reliable connections.

3. Electromagnetic Interference (EMI) and Noise

Industrial control systems must resist interference from other equipment to ensure accurate and reliable operation.

Solutions:

- Advanced Layer Stacking: We design multilayer PCBs with proper grounding and shielding to minimize EMI.

- Controlled Impedance: Our expertise in impedance-controlled designs ensures signal integrity, even in noisy industrial environments.

- Stringent Testing: Every PCBA undergoes EMI testing to ensure compliance with industry standards.

4. Compliance with Industrial Standards

Industrial control PCBA must meet specific standards such as IPC Class 2 and Class 3, CE, UL, and other certifications to ensure safety and reliability.

Solutions:

- ISO Certified Facility: Our factory is ISO 9001-certified, reflecting our commitment to quality.

- CE and UL Certifications: We provide PCBAs that meet CE and UL standards for industrial safety and performance.

- Traceability: Each PCBA is produced with detailed documentation and traceability to meet regulatory and customer requirements.

Why Choose Ring PCB for Industrial Control PCBA?

1. Extensive Experience

With over 15 years of expertise, Ring PCB has a proven track record of delivering top-quality PCB and PCBA solutions for industrial control systems.

2. State-of-the-Art Facility

Our Shenzhen factory is equipped with advanced machinery for PCB manufacturing, SMT assembly, and thorough testing, ensuring unmatched precision and reliability.

3. Comprehensive Services

We offer end-to-end solutions, including:

- PCB Manufacturing

- Component Procurement

- SMT and Through-Hole Assembly

- Testing and Quality Assurance

4. Global Reach and Timely Delivery

With a 99.6% on-time delivery rate and express global shipping, we ensure your projects stay on schedule.

Success Stories

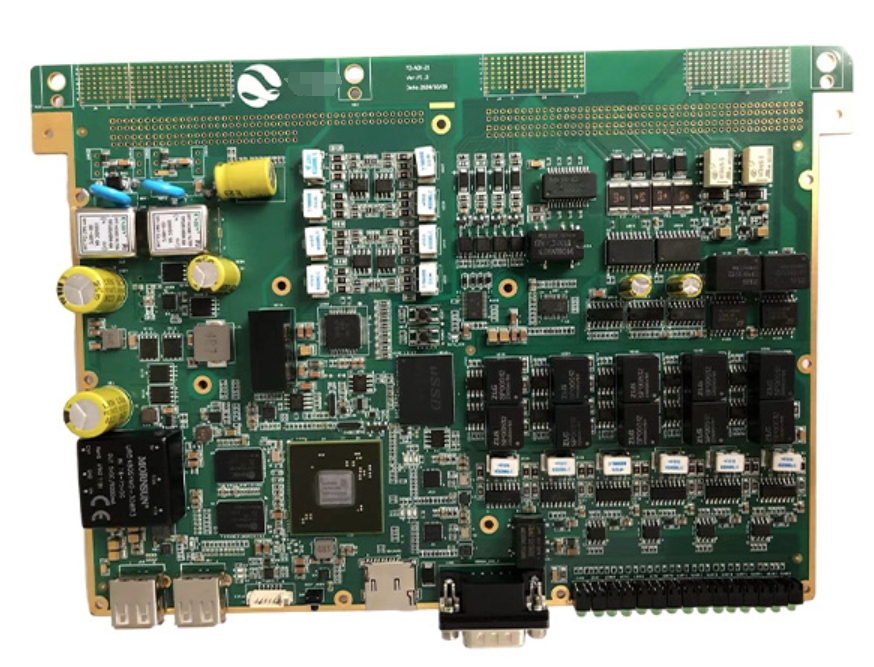

Industrial Control PCBA