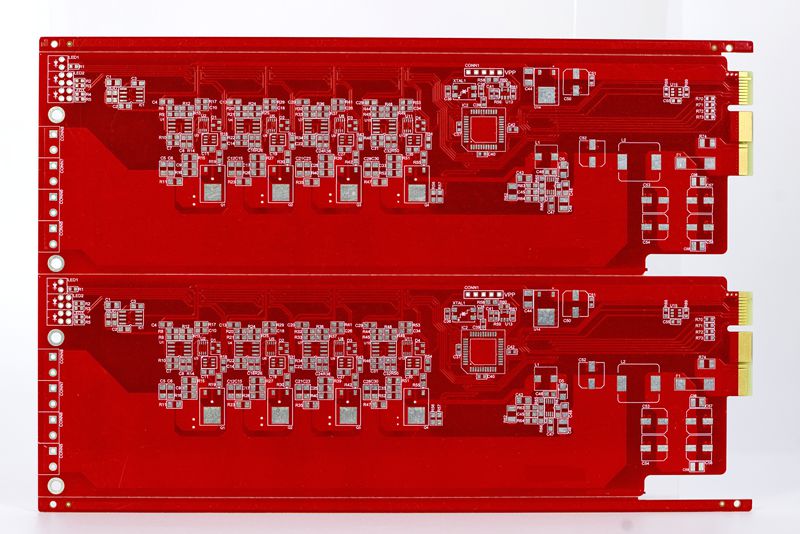

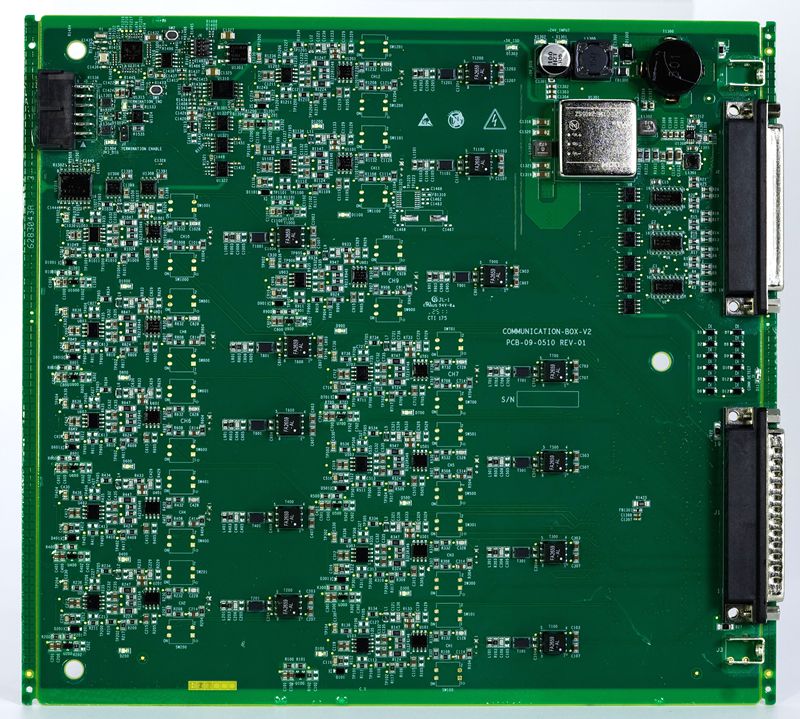

Communication devices are at the heart of the modern digital age, enabling seamless connectivity across the globe. Communication PCBA requires precision, advanced technology, and strict adherence to performance standards. Since 2013, Ring PCB’s Shenzhen factory has specialized in manufacturing high-quality communication PCBAs, offering solutions tailored to the unique demands of the communication industry.

The Importance of Communication PCBA

Communication PCBAs are used in a wide array of devices, including:

Base Stations for mobile networks.

Routers and Modems for internet connectivity.

Satellite Communication Systems for global coverage.

Optical Networking Equipment for high-speed data transfer.

IoT Devices that connect smart technologies.

Challenges in Communication PCBA Manufacturing

1. High-Speed Signal Integrity

Communication systems rely on high-frequency signals that must remain intact during transmission. Signal loss or distortion can compromise performance.

Ring PCB Solution:

1. We use controlled impedance PCB designs to maintain signal quality.

2. Our manufacturing process minimizes signal noise with low-loss materials like Rogers, Isola, and Nelco laminates.

3. Advanced testing, including TDR (Time Domain Reflectometry), ensures signal integrity across all communication PCBAs.

2. Thermal Management

High-speed communication systems generate significant heat, particularly in densely packed PCBAs. Effective thermal management is essential to avoid overheating.

Ring PCB Solution:

1. We incorporate copper heat sinks, thermal vias, and aluminum-backed PCBs to dissipate heat efficiently.

2. Our 8-stage lead-free reflow soldering process ensures that components withstand thermal cycling without degradation.

3. Miniaturization and High-Density Interconnects (HDI)

Modern communication devices demand compact and lightweight PCBAs with high component density.

Ring PCB Solution:

1. Our Shenzhen factory specializes in HDI PCB manufacturing, employing microvias, blind/buried vias, and fine-pitch technology.

2. We design and assemble multi-layer PCBs (up to 48 layers) to support compact yet powerful systems.

4. Environmental Resistance

Communication equipment often operates in harsh environments, including outdoor and industrial settings where humidity, dust, and temperature fluctuations are common.

Ring PCB Solution:

1. We offer conformal coatings and encapsulation services to protect PCBAs from environmental damage.

2. Rigorous testing, including environmental simulation and thermal shock testing, ensures durability.

5. Power Efficiency

Communication systems require PCBAs that optimize power usage to maintain operational efficiency and extend device life.

Ring PCB Solution:

1. We design power-efficient PCBs with optimized copper traces for low resistance.

2. Advanced components and power management techniques reduce overall energy consumption.

6. Regulatory Compliance

Communication PCBAs must adhere to strict standards such as RoHS, REACH, and telecom-specific certifications.

Ring PCB Solution:

1. Our processes comply with global standards, including RoHS for lead-free and environmentally friendly production.

2. Our factory’s IATF 16949 certification ensures adherence to stringent quality controls.

Why Choose Ring PCB for Communication PCBA?

1. Advanced Equipment and Expertise

SMT (Surface Mount Technology): High-precision pick-and-place machines ensure accuracy in component placement.

Automated Optical Inspection (AOI): Our AOI systems guarantee defect-free assemblies.

X-ray Inspection: We use X-ray technology to verify the quality of solder joints in complex assemblies.

2. Experienced Team

Our engineers collaborate with clients to design, test, and optimize communication PCBAs, ensuring superior performance and cost efficiency.

3. End-to-End Services

Ring PCB provides a turnkey solution, from component procurement to final assembly and testing. Customers only need to supply their design files, and we handle the rest.

Ring PCB delivers professional and reliable turnkey PCBA services.

With 17 years of industry experience, Ring PCB provides PCB manufacturing, processing, precision SMT assembly, and on-demand customization. Our Shenzhen and Zhuhai factories total 5,000+ m² and employ 500 people. All PCB and PCBA products meet international industry standards. We offer 3-day quick prototyping, 7-day mass production, flexible order quantities, and fully customizable full-turnkey PCBA solutions. We look forward to working with you.

📧 Contact: rfq@ringpcb.com

🌐 Website: https://www.ringpcb.com