Our Global Partners

About Ring PCB

Founded in 2008, Ring PCB is a professional PCB & PCBA manufacturer based in Shenzhen, China, specializing in printed circuit board fabrication and full-turnkey PCB assembly services. With 18 years of industry experience, we deliver reliable and scalable electronic manufacturing solutions to customers worldwide.

We operate a 10,000-square-meter self-operated manufacturing facility with a skilled team of 500 employees, supported by advanced production and inspection equipment. From 3-day rapid prototyping to mass production, our in-house capabilities ensure stable lead times, strict quality control, and flexible manufacturing support.

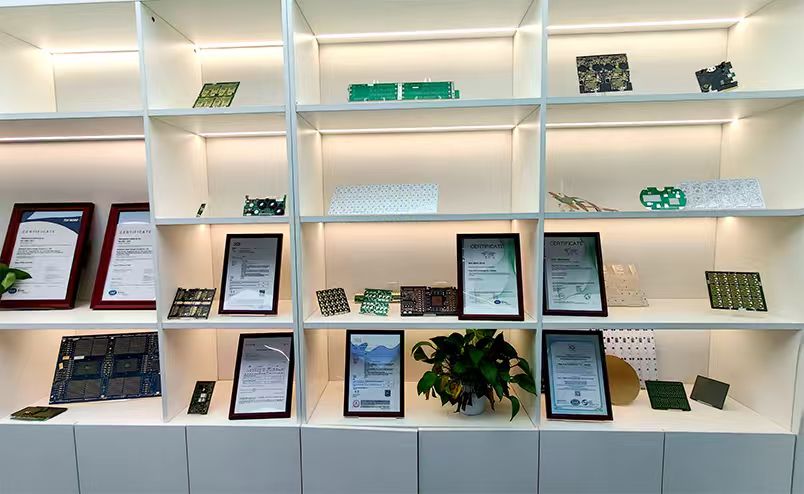

Certified to ISO9001, ISO14001, ISO13485, IATF16949, and UL standards, Ring PCB provides high-quality PCB and PCBA solutions and is a trusted EMS partner for global customers.

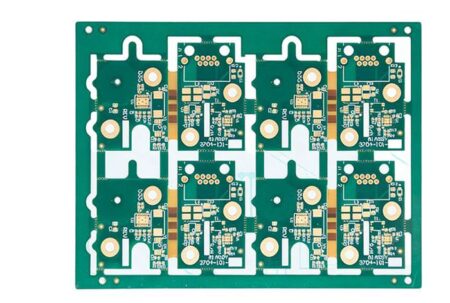

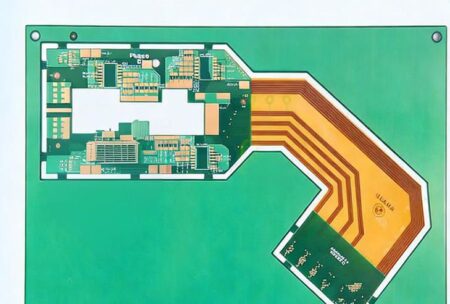

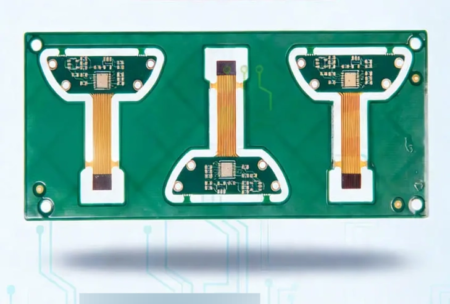

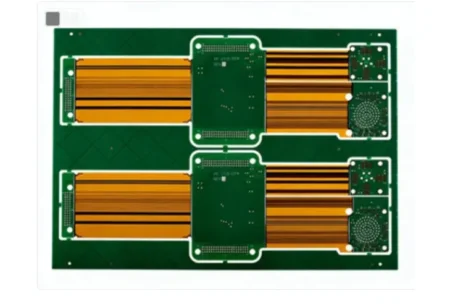

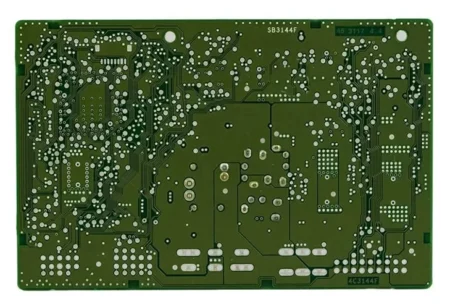

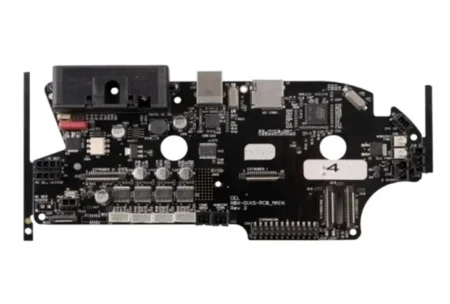

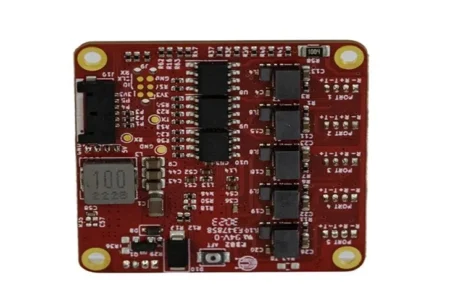

Latest Products

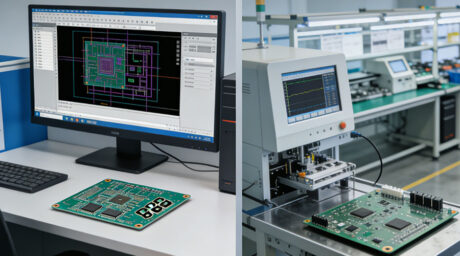

One-Stop PCB Manufacturing & Assembly

We ensure streamlined, end-to-end PCB and PCBA services under one roof.

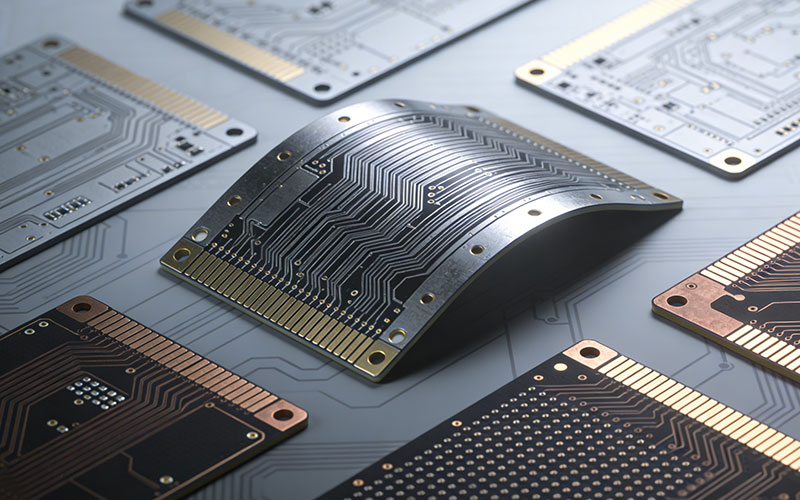

PCB Manufacturing

Ring PCB provides reliable, high-quality printed circuit board manufacturing, certified with UL approval. Our offerings include:

- 2-48 Layer Rigid PCBs: Suitable for complex, multilayer designs.

- Flex-Rigid PCBs: Combining flexibility and rigidity for versatile applications.

- Heavy Copper PCBs: Ideal for high-power applications due to enhanced current-carrying capacity.

- HDI PCBs: High-Density Interconnect PCBs, supporting intricate, space-saving designs.

- etc.

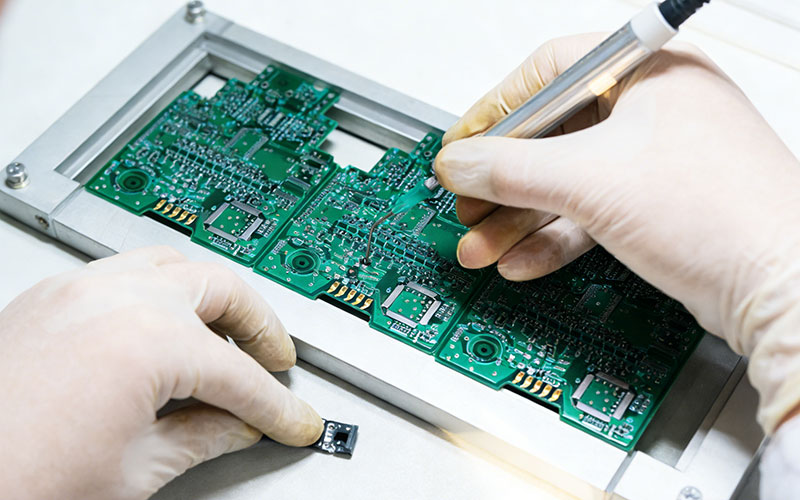

PCB Assembly

Ring PCB prioritizes high-quality assembly, incorporating multiple inspection steps to ensure precision:

- SPI 3D Inspection: Performed after solder paste printing to verify paste quality and placement.

- AOI Inspection: Conducted after assembly to detect any component misplacement or soldering defects.

- LCR Inspection: The first piece of each order undergoes LCR (inductance, capacitance, resistance) testing to ensure component accuracy.

- X-Ray Inspection for BGA: All products containing BGAs (Ball Grid Arrays) are examined using X-ray to verify internal connections.

Components Sourcing

Ring PCB sources electronic components directly from first-hand agents, reputable platforms, and original manufacturers, ensuring authenticity and quality. With 16 years of purchasing experience, Ring PCB has established a strong network of high-quality suppliers.

Our sourcing process includes rigorous incoming material inspections, and if required, we work with electronic component inspection agencies to further verify component reliability.

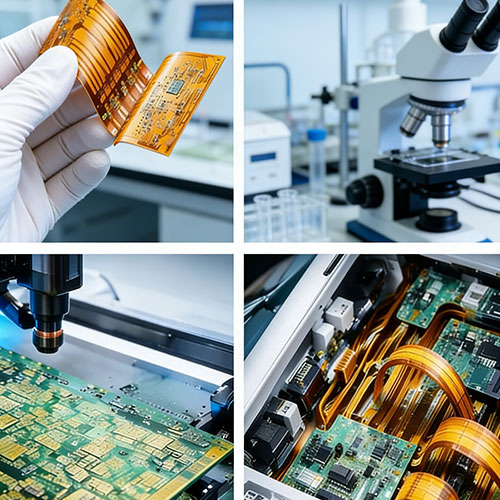

Full Turn- key

In response to growing demand, Ring PCB began offering full turn-key services 8 years ago, adding dedicated product assembly lines. This comprehensive service covers:

- PCB Manufacturing

- Electronic Components Procurement

- PCB Assembly

- Box-Building

With these integrated capabilities, Ring PCB provides customers with a complete, reliable, and high-quality full turn-key solution, streamlining every step from production to final products.

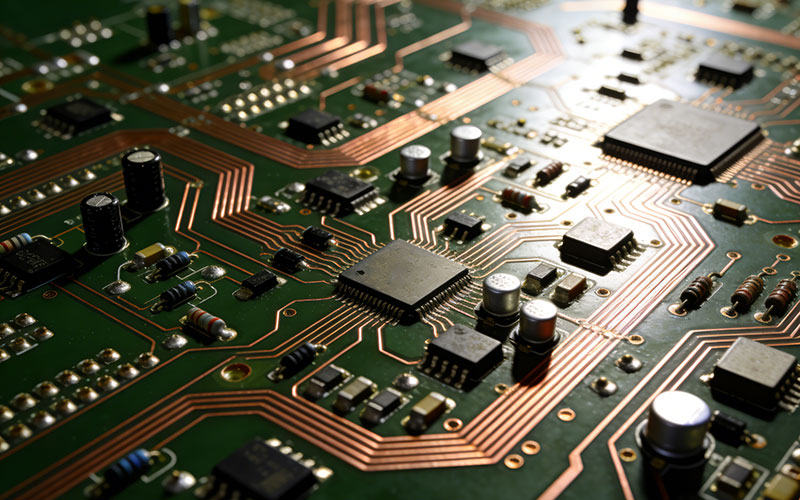

Factory Overview

A modern PCB manufacturing facility in Shenzhen, equipped with advanced production lines and strict quality control, delivering reliable and scalable PCB and PCBA solutions worldwide.

Ring PCB Blog

Discover updated blog related to PCB, assembly, manufacturing and more...

PCB Manufacturing: The Foundation of Reliable EMS Solutions

PCB & PCBA Manufacturing: From Rapid Prototyping to Scalable Mass Production

Customer Q&A

Have questions? You’re welcome to reach out to us directly here.

Asking Questions

What Does PCBA Mean?

PCBA stands for Printed Circuit Board Assembly, which refers to the process of mounting electronic components onto a bare PCB through SMT, THT, or mixed assembly methods, making the board fully functional.

What’s the Difference Between PCB and PCBA?

A PCB is an empty circuit board without components, while PCBA is the finished product with all electronic components assembled and soldered onto the board, ready for testing and use.

How to Choose the Right PCBA Manufacturer?

When selecting a PCBA manufacturer, key factors include production capacity, equipment level, quality control processes, engineering support, certifications, and experience with global customers.

What PCBA Services Does Ring PCB Provide?

Ring PCB offers one-stop PCBA solutions, including PCB fabrication, SMT & THT assembly, component sourcing, functional testing, and quality inspection for prototypes, small batches, and mass production.

How to Order PCB Assembly Services from Ring PCB?

Simply submit your Gerber files, BOM, and project requirements. Our team will review your design, provide a quotation, and guide you through the production and delivery process step by step.

Do You Support Prototype and Low-Volume PCBA Orders?

Yes. We support rapid prototyping and low-volume production, helping customers validate designs before moving into large-scale manufacturing.

What Quality Control Measures Are Used in PCBA Production?

Our quality control process includes AOI inspection, X-ray inspection, functional testing, and strict process monitoring to ensure consistent quality and reliability.